Label makers have evolved remarkably over centuries, transforming from primitive hand-carved labels to advanced digital devices. These indispensable tools have revolutionized organization, manufacturing, and retail. Let’s take a journey through the rich history of label makers, exploring their origins, key innovations, and their impact on industries worldwide.

Label Makers in Ancient Times: The Birth of Organization

In ancient civilizations, the concept of labeling existed long before modern technology. People used primitive methods to mark ownership and identify items. The earliest label-making techniques involved carving or engraving symbols onto materials like wood, clay, or stone. While these labels were far from today’s sleek, customizable options, they served an essential purpose—organizing and identifying items.

These early labels were often attached to goods using strings or primitive adhesives. They were primarily used in trade, where identifying the ownership or contents of goods was crucial. This system, though labor-intensive and limited in design, laid the foundation for the modern labeling systems we use today.

The Rise of Industrial Label Makers: Revolutionizing Production

Fast forward to the Industrial Revolution, and the world of labeling experienced a dramatic shift. The mass production of goods required efficient methods for labeling products, tools, and containers. This gave rise to the first industrial label makers, which were rudimentary machines but significantly more efficient than manual labor.

These early machines were often hand-operated, using interchangeable metal or wooden types to stamp information onto labels. The impact was profound—manufacturers could now label large volumes of products quickly and accurately, reducing human error. This period marked the beginning of automated labeling systems, which streamlined production processes and set the stage for modern industry standards.

Innovations in Label Making Technology: The Digital Leap

As industries grew and technology advanced, so did label-making technology. One of the most significant breakthroughs was the advent of digital label printers. Unlike the manual, labor-intensive methods of the past, digital printers offered precision, speed, and customization.

Digital label printers employ techniques like inkjet or laser printing, allowing businesses to produce high-quality, full-color labels. Whether it’s a simple barcode or a complex design, digital printing offers endless customization options, including various shapes, sizes, and materials. This innovation has been a game-changer for industries like retail and manufacturing, where efficient and accurate labeling is crucial.

Additionally, label design software became widely available, empowering users to create professional-looking labels without specialized training. These programs offer templates, fonts, and graphic options, making it easier than ever to align labels with branding strategies. Features like barcode generation and database integration have further enhanced productivity, enabling seamless tracking of inventory and products.

The Impact of Label Makers on Retail and Packaging

Label makers have significantly influenced the retail and packaging industries. Walk into any retail store today, and you’ll find aisles filled with neatly labeled products, thanks to modern label makers. These labels not only provide essential information but also play a role in brand identity and customer engagement.

In retail, efficient labeling helps consumers find products more easily, streamlining their shopping experience. Clear, well-organized labels ensure that items are correctly identified, reducing confusion and enhancing customer satisfaction. Additionally, the ability to create customized labels has enabled retailers to elevate their branding efforts, ensuring that labels are consistent with their visual identity.

In packaging, label makers have improved accuracy and compliance with industry regulations. Manufacturers can quickly produce detailed labels that include product information, safety instructions, and regulatory requirements. This has enhanced consumer trust, as clear labeling ensures transparency regarding product contents and origins.

Label Makers During the Industrial Revolution: A Game Changer

The Industrial Revolution was a pivotal period for label-making technology. As factories became more mechanized, the demand for efficient labeling systems surged. Early label makers of this era were simple machines designed to imprint basic information onto items like crates and containers.

These machines drastically improved efficiency compared to handwritten labels, which were prone to errors. Industrial label makers made it possible to apply consistent, legible labels in large quantities, reducing mistakes and enhancing the organization of goods. This advancement was a critical step in modernizing industrial processes and logistics.

The Evolution of Label Makers in the Digital Age

In the digital age, label makers have undergone yet another transformation. With the rise of computerized systems, the manual label machines of the past are being replaced by faster, more efficient digital devices. These computerized label makers have automated much of the process, allowing businesses to produce labels with minimal human input.

One of the most significant advancements in this era has been the integration of wireless and mobile technologies. Modern label makers can now connect to smartphones, tablets, and computers, enabling real-time label printing from virtually anywhere. This level of convenience has made it easier for businesses to keep up with the fast-paced demands of today’s market, whether in retail, manufacturing, or logistics.

The Role of Label Makers in Enhancing Productivity

In today’s workplaces, label makers are indispensable tools for enhancing organization and productivity. From labeling files and folders to organizing storage spaces, these machines offer unmatched flexibility and efficiency. Modern label makers allow users to customize labels with various fonts, colors, and symbols, creating a visually appealing and practical organizational system.

The biggest advantage? Time-saving capabilities. Employees no longer have to handwrite labels or struggle to maintain legibility across different departments. Instead, with just a few clicks, they can produce professional-looking labels that help streamline daily tasks and maintain order. This boost in productivity translates to cost savings and improved operational efficiency across various industries.

Conclusion: The Unstoppable Evolution of Label Makers

From the ancient world’s carved stones to today’s sleek digital devices, label makers have come a long way. These tools have transformed industries, improving efficiency, organization, and productivity in ways that couldn’t have been imagined centuries ago. As technology continues to advance, the future of label makers looks bright, with possibilities like AI-driven designs and smart label integration on the horizon. One thing is certain: label makers will remain an essential part of both personal and professional organization, helping industries stay efficient and well-organized for years to come.

My Husband Brought Home a Pregnant Lover and Told Me to Move to My Mom’s – My Revenge Was Harsh

Eight years of marriage shattered in one quick breath when my husband Mike brought home his pregnant sidekick and KICKED ME OUT of the house. I packed alright, but what I unpacked was a revenge plot so brilliant and karmic!

Portrait of a sad young woman | Source: Midjourney

It was a Tuesday evening when my life decided to go off the rails. I walked into our living room, tired from a long day at work, only to find a heavily pregnant woman sitting on our couch, eating chips.

At first, I thought maybe I’d accidentally wandered into the wrong house.

But no, there was our ugly floral wallpaper that Mike insisted on keeping, and there was Mike, looking like he’d just swallowed a porcupine.

A pregnant woman sitting on the couch | Source: Midjourney

“Hey, Michelle,” he said, his voice as casual as if he was asking me to pass the salt. “We need to talk.”

I stood there, frozen, my brain trying to compute the scene before me. The pregnant woman smiled awkwardly, her hand on her belly, looking like she was auditioning for a soap opera.

“This is Jessica,” Mike continued, gesturing to the human incubator on our couch. “She’s pregnant. With my child. It… it just happened. And we’ve decided to be together.”

A woman gaping in shock | Source: Midjourney

I waited for the punchline. Surely, this was some elaborate prank for a new reality TV show. Maybe I’d win a car if I didn’t freak out?

But Mike’s face remained serious, and Jessica kept smiling that infuriating smile.

“Mike,” I said slowly, “what do you mean by ‘it just happened’? Did you trip and fall into her—?”

Mike had the audacity to look offended. “Enough, Michelle! This is serious. I think it’s best if you move out. You can go stay with your mom. Jess and I’ll take over the house.”

A serious-looking man sitting on the couch | Source: Midjourney

I blinked. Once. Twice. Three times. Nope, still not a dream.

I was half-expecting Ashton Kutcher to jump out and tell me I’d been Punk’d. But alas, no Ashton. Just my cheating husband and his very pregnant sidekick.

“Alright,” I calmly said. “I’ll pack my things and leave.”

Mike looked relieved, probably thinking he’d gotten off easy. Jessica’s smile grew wider, like she’d just won the lottery. Little did they know, the lottery was about to hit them back, and hit them hard.

A heartbroken woman at the doorway | Source: Midjourney

I went upstairs, packed a suitcase with some essentials, and left without another word.

As I drove to my mom’s house, the shock wore off, and rage took its place. But this wasn’t just any rage. This was the kind of rage that makes you want to do something spectacularly stupid and incredibly satisfying.

The next day, I set my plan in motion.

First stop: the bank. I marched in there like a woman on a mission, which I was. I froze our joint account faster than you can say “cheating jerk.”

The look on the bank manager’s face when I explained why was priceless. I’m pretty sure he was mentally taking notes for his next novel.

A woman outside a bank | Source: Midjourney

Next, I visited a locksmith.

I remembered overhearing Mike tell Jessica they’d be gone for three days, giving me plenty of time to execute my master plan. It was like the universe was conspiring in my favor, and who was I to argue with destiny?

My next stop: my house. The same cozy house Mike and I once lived together, planning a future that was now a total trainwreck.

The puzzled locksmith probably thought I was crazy, cackling as I had him change all the locks on the house. I may have gone a bit overboard and asked for the most complicated, high-tech locks available. Hey, if I was going to do this, I was going to do it right. And big.

A locksmith fixing a door lock | Source: Midjourney

Then came the movers.

I gave them the spare keys and scheduled them to pack up everything I owned, which was basically everything in the house. I even took the toilet paper. Let’s see how Mike and Jessica enjoy using leaves!

But the piece de resistance? Oh, that was yet to come. I had a brilliant idea that would make this revenge not just sweet, but long-lasting.

Toilet paper rolls in a basket | Source: Midjourney

I sent out party invitations. Lots of them. To Mike’s family, our friends, his coworkers, even that nosy neighbor who always complained about our late dog.

The invitation read: “Come celebrate Mike’s new life! Surprise party at our house, tomorrow at 7 p.m.!”

A party invitation | Source: Midjourney

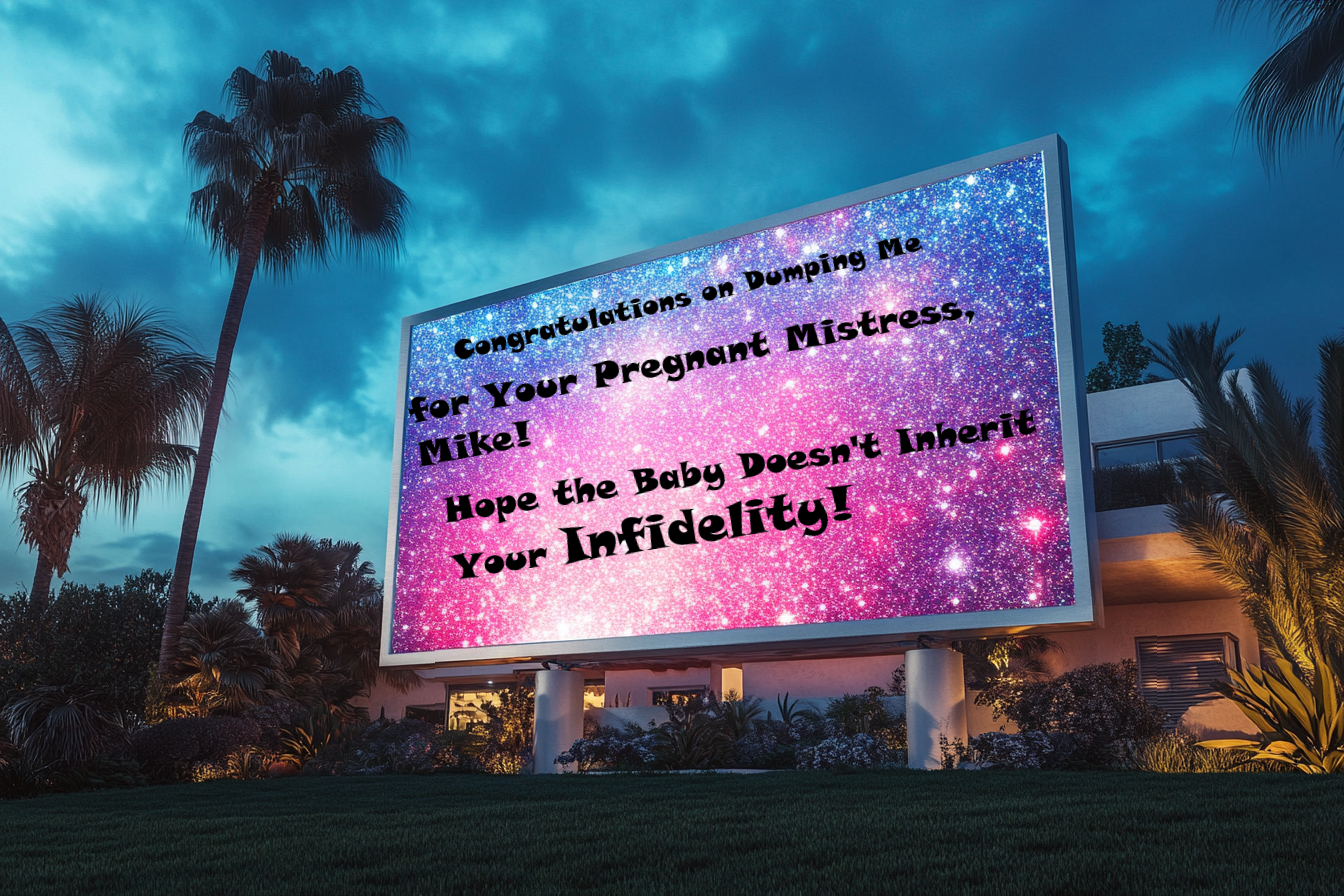

Then, I commissioned a billboard. Yes, a billboard. A huge one. It was delivered and set up on our front lawn, impossible to miss.

In giant, bold letters, it proclaimed: “Congratulations on Dumping Me for Your Pregnant Mistress, Mike! Hope the Baby Doesn’t Inherit Your Infidelity!”

I stepped back to admire my handiwork, feeling like a mischievous fairy godmother who’d just granted the world’s most ironic wish. With a satisfied smirk and a dramatic hair flip, I sashayed away from the scene, eagerly anticipating the chaos that was about to unfold.

A billboard outside a house | Source: Midjourney

The next evening, right on cue, my phone rang. It was Mike, and he sounded like he was having an aneurysm.

“Michelle!” he screeched, his voice hitting octaves I didn’t know he could reach. “What the hell is going on? Why are there people at our house? And what’s with this insane billboard?”

“Oh, that?” I said, trying to sound innocent. “Just a little housewarming party for you and Jessica. Don’t you like the decorations?”

“Decorations? It’s a freaking circus out here! And why can’t I get into the house?”

A startled man talking on the phone | Source: Midjourney

I couldn’t help but giggle. “Well, honey, you told me to move out, remember? You never said anything about you staying there. I just remembered that the house is solely under my name. So, I changed the locks. Oopsie!”

There was a long silence on the other end. I could almost hear the gears in his tiny brain trying to process what was happening.

“Where are we supposed to go?” he finally sputtered.

“Gee, I don’t know, Mike. Maybe Jessica’s mom would love to have you? I hear pregnancy hormones and in-laws mix really well.”

A smiling woman talking on the phone | Source: Midjourney

I hung up, feeling lighter than I had in years. But wait, there was more!

In the days that followed, I had the utilities cut off, canceled the cable, and made sure all our joint assets were transferred into my name. I listed the house for sale, making sure to mention in the listing that it came with a “bonus front lawn art installation.”

I had Mike served with divorce papers at work. I specifically requested the mailman to dress up as a pregnant woman. Just for funsies.

But the universe wasn’t done with Mike yet. Oh no, it had saved the best for last.

A man gaping in shock as he holds some papers | Source: Midjourney

A week later, I got a call from Jessica. Yes, that Jessica. She was crying so hard I could barely understand her.

“Michelle,” she sobbed, “I’m so sorry. I didn’t know… I mean, Mike told me you two were separated. And now… now he’s broke and homeless, and I’m pregnant, and I don’t know what to do!”

I almost felt bad for her. Almost.

“Well, Jessica,” I said, trying to keep the glee out of my voice, “I hear the circus is always looking for new acts. Maybe you two could start a juggling duo? You juggle the baby, he juggles his lies?”

She didn’t appreciate my humor. Tsk! Tsk!

Silhouette of a pregnant woman holding a smartphone | Source: Midjourney

As it turns out, when Jessica found out that Mike was now homeless, broke, and the laughingstock of the town, she decided that maybe being with a guy who had no money, no house, and no future wasn’t such a great idea after all.

She dumped him faster than you can say “Karma’s a b****!”

Last I heard, Mike was living in a tiny apartment, trying to scrape together enough money to pay bills and feed his hungry belly. His family had cut him off, disgusted by his behavior.

They even sent me a fruit basket and a sorry card. I ate the fruits while soaking in my new jacuzzi.

As for me? Well, the house sold for a nice profit. I moved to a beautiful new place, started my own business, and adopted a cat. I named him Karma.

A woman with her pet cat | Source: Midjourney

So yeah, my revenge might have been a bit over the top. But let’s be real, bringing home a pregnant mistress and trying to kick me out of my own house? That’s not just crossing a line, that’s pole-vaulting over it and then setting the pole on fire.

In the end, I learned a valuable lesson: When life gives you lemons, don’t just make lemonade. Squeeze those lemons into the eyes of those who wronged you, and then sit back and watch them stumble around blindly. It’s much more satisfying.

And remember, folks: cheaters never prosper, but the cheated-on with a good sense of humor and a flair for the dramatic? Oh, we do just fine!

A cheerful woman smiling | Source: Midjourney

This work is inspired by real events and people, but it has been fictionalized for creative purposes. Names, characters, and details have been changed to protect privacy and enhance the narrative. Any resemblance to actual persons, living or dead, or actual events is purely coincidental and not intended by the author.

The author and publisher make no claims to the accuracy of events or the portrayal of characters and are not liable for any misinterpretation. This story is provided “as is,” and any opinions expressed are those of the characters and do not reflect the views of the author or publisher.

Leave a Reply